Dog food making machine

Dog food making machine is widely used in dog food production., gatos, pieces, birds and various pets. It is an ideal choice for different manufacturers. Fish feed processing machine can adjust raw materials, the temperature, humidity and other process parameters, so that the product has the features in a novel way, texture, rich nutrition and delicate organization, which is suitable for the use of different fish.

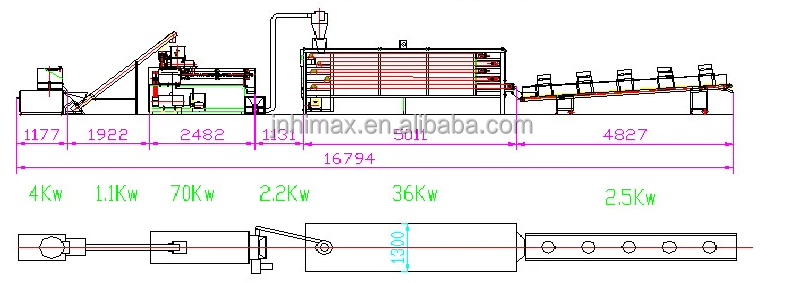

Pet food extruder production process

Feeder → Sprayer series group → Intermediate storage container → Screw feeder → Ribbon mixer → Bucket elevator → Twin screw extruder → Air conveyor → Steam dryer or electric heating dryer or hot air dryer → Conveyor Air → Counterflow Chiller → Vertical Oil Mixer → Vibrating Screen Bucket → Elevator → Food Packaging Machine

Machine for making raw material dog food

Pet food processing line can use meat meal, fish flour, corn powder, soybean meal and other grain powder as raw material to produce dry pet food, as dog food, gatos, fish and birds. , etc. You can also use meat, bones, animal viscera, fish, vegetables, fruits, etc. to produce pet food.

Features of dog food production line.

1. The main extruder adopts frequency speed control with high automation and stable performance.

2. The screws are made of alloy steel and special craftsmanship, long lasting use, high pressure, screw life is longer. Adopting the structure of building blocks and combining them voluntarily according to different demands.

3. Forced lubrication system can ensure longer service life of equipment transmission.

4. Automatic temperature control system makes temperature control more direct and parameter more precise.

5. Self-cleaning, when stopping, can be cleaned without disassembling.

6. According to different screw design rates to meet different technology requirements.

7. This equipment has a wide variety of materials, products of multiple shapes and flexible combinations. We can produce different products according to different models and combinations.

Technical parameters

| Model | HM65 | HM70 | HM85 | HM95 |

| Input voltage | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz |

| Installed potency | 70kw | 90kw | 120kw | 180kw |

| Power consumption | 40kw | 50kw | 100kw | 120kw |

| Ability | 120-150kg/h | 200-250kg/h | 400-500kg/h | 800-1000kg/h |

Final product