Cat food production line

With more and more types of pets, People's demand for pet food is also becoming more diverse. To meet various feeding needs, Our company has developed a pet food production line, which is easy to operate, has a friendly human-machine interface, precise control and ensures pet food is processed under temperature, pressure, humidity and other stable environments. .

Our company's cat food production line adopts the most advanced inflation technology. Good technology can reduce nutrition loss, in order to guarantee good palatability and meet the physiological characteristics of pets. From the grinding of the raw material, then the mix, extrusion and cutting, drying and blowing, spraying oil on the surface, sealing and packaging, every step is strictly controlled.

Raw material of cat food production line

Pet food processing line can use meat meal, fish flour, corn powder, soybean meal and other grain powder as raw materials to produce dry pet food, like dog food, gatos, pieces, birds, etc. You can also use meat, bones, animal viscera, fish, vegetables, fruits, etc to produce pet food.

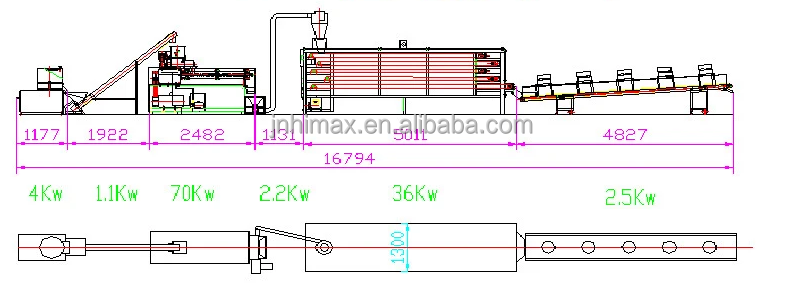

Cat Food Process Line Flowchart

Double screw extruder → Air conveyor → Dryer → Hoister → Flavoring machine → Hoister → Cooler → Packing machine

Technical parameter

| Model | HM65 | HM70 | HM85 | HM90 | HM95 |

| Input voltage | 380v/50hz | 380v/50hz | 380v/50hz | 380v/50hz | 380v/50hz |

| Installed potency | 70kw | 90kw | 120kw | 96kw | 180kw |

| Power consumption | 40kw | 50kw | 100kw | 80kw | 120kw |

| ability | 120-150kg/h | 200-250kg/h | 400-500kg/h | 800-1000kg/h | 800-1000kg/h |

| dimension | 2200*120*220(cm) | 2400*150*220(cm) | 2800*350*230(cm) | 3000*350*230(cm) | 4500*250*250(cm) |

Features of cat food production line

1. Pre-curing treatment function. Not only is the maturity of pet food improved, but also improves performance.

2. Frequency conversion speed regulation, high degree of automation and stable performance.

3. The screws are made of alloy steel and special technology, that is durable, high pressure and the life of the screws is longer. Adopt a building block structure, which can be arbitrarily combined according to different needs.

4. Forced lubrication system can ensure longer life of equipment transmission.

5. Automatic temperature control system makes temperature control more intuitive and parameters more precise.

6. Self-planting, can be cleaned without disassembling it when turning it off.

7. According to different screw design speeds, different process requirements can be met.

8. The equipment has a wide range of materials, Various product shapes and flexible placement. We can produce different products according to different models and locations.

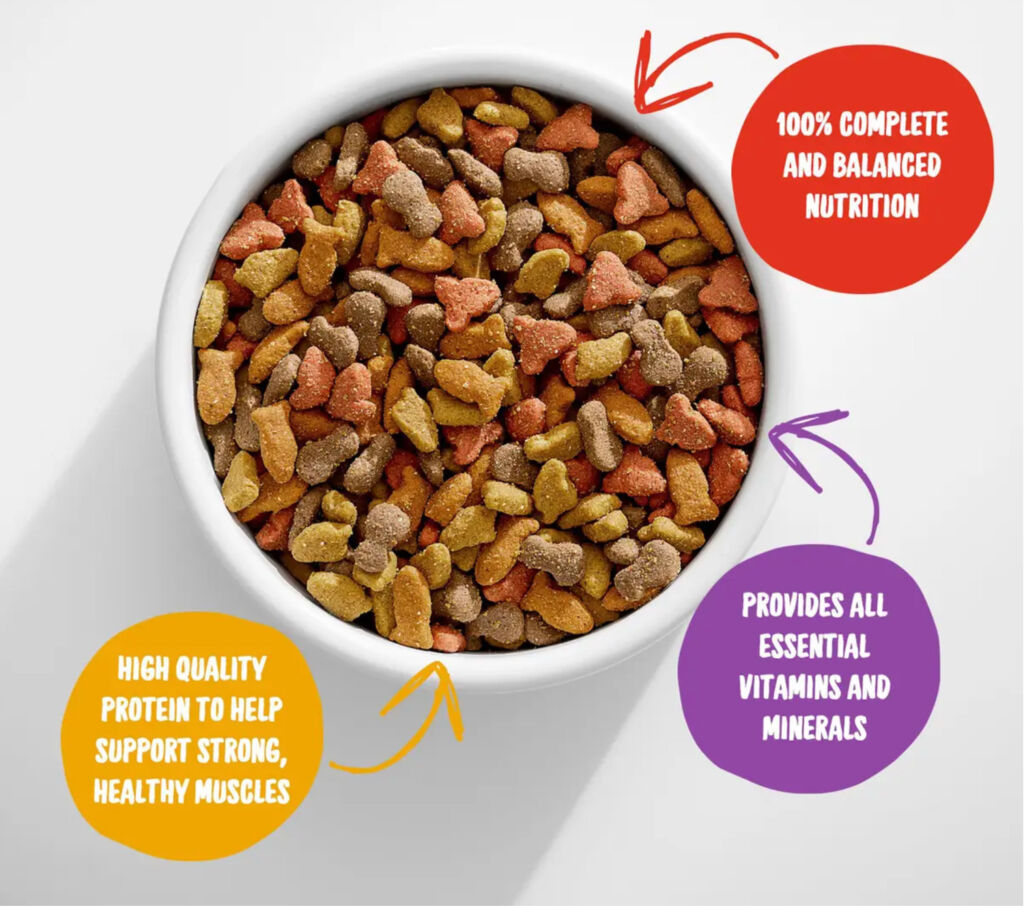

Finished product